INFOMERCIAL PRODUCTS

We handle every stage of the creative process, from concept development, research and chemical production, testing analysis, manufacturing, packaging, infomercial film production and distribution.

Our truly unique range of products reach the home end user via TV Retail/ Internet /Radio/ Print /Live Shopping Channels.

To partner with us and become a supplier or distributor kindly contact us and our marketing division will discuss your requirements.

KONTA PAINT have developed a complete new range of innovative specialist coatings that transform, protect and enhance any surface in the home.

Our technical development and research has culminated in the creation of unique quality paints and coatings that have been introduced into the retail sector for both the DIY and Industrial contractor market.

INFOMERCIAL WOOD FIX KOTE

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL WOOD FIX KOTE

INFOMERCIAL PRODUCT DESIGN

BEFORE

AFTER

INFOMERCIAL WOOD FIX KOTE

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL FLOOR SHINE

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL FLOOR SHINE

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL FLOOR SHINE

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL FLOOR SHINE

INFOMERCIAL PRODUCT DESIGN

BEFORE

AFTER

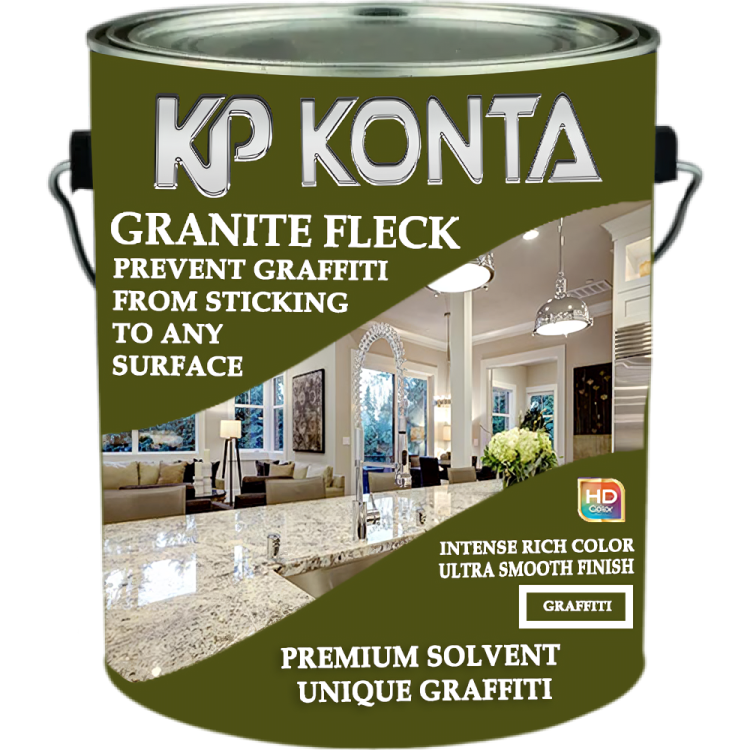

INFOMERCIAL GRANITE FLECK

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL GRANITE FLECK

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL GRANITE FLECK

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL GRANITE FLECK

INFOMERCIAL PRODUCT DESIGN

INFOMERCIAL PRODUCTION

A successful infomercial production will always start with a viable product. Packaging and mass marketability are the elements your product must have.

Then a company must find an experienced infomercial production company. At this point, the clients will present the detailed information about the product. This also includes the pricing and offers (the critical elements in determining the success or failure).

In the infomercial production process budget is one of the most important things. The budget will determine the type of infomercial production and talent they can afford in developing the infomercial. Once the budget is agreed upon, creative strategy begins.

This includes the script treatment, storyboarding, talent selection, location scouting, shooting, and editing.

While these may seem very simple to determine, there are a number of issues to keep in mind. Obviously the first is profit against the COGS (cost-of-goods-sold) number.

Paint Manufacturing Process

The process of manufacturing paint is a multifaceted and intricate one, encompassing numerous steps and materials to achieve a top-notch end product. Starting from the careful selection of raw materials to the meticulous mixing and blending of different components, every stage in this process holds immense significance in shaping the ultimate properties of the paint. In this article, we will delve deeper into the different phases involved in the paint manufacturing process and explore how they synergistically contribute to crafting a resilient and visually appealing coating suitable for various surfaces.

Raw Materials and Their Preparation

Paint is typically made from a combination of raw materials, including solvents, pigments, binders, and additives. These raw materials are carefully selected and combined in precise proportions to create the desired properties and characteristics in the finished paint.

The specific raw materials used in paint manufacturing will vary depending on the type of paint being produced. For example, the raw materials used in water-based latex paint production will be different from those used in oil-based alkyd paint.

List of Raw Materials Used in the Paint Manufacturing

There are many different raw materials that are combined and used in the preparation of paint.Some common raw materials used in paint manufacturing include:

Solvents

Solvents are used to dissolve the other ingredients in the paint and control the consistency of the finished product. Common solvents used in paint include water, alcohol, and mineral spirits.

Pigments

Pigments are the colorants that give the paint its color. They are typically finely ground minerals or chemicals that are insoluble in the paint’s solvent. Common pigments used in paint include titanium dioxide, zinc oxide, and iron oxide.

Binders

Binders are the glue that holds the pigments together and adheres the paint to the surface it is applied. Common binders used in paint include latex, acrylics, and alkyds.

Additives

Additives are substances added to the paint to improve its performance or alter its properties. Common additives used in paint include preservatives to prevent mold growth, flow agents to improve the paint’s application properties, and UV absorbers to protect against fading from sunlight.

Process of Paint Manufacturing

To prepare these raw materials for use in paint manufacturing, they must undergo several processing steps. This typically involves grinding and mixing the pigments and other ingredients to create a homogeneous mixture. The resulting paint base is then packaged and shipped to paint manufacturers, where it is further processed and combined with additional ingredients to create the final paint product. The paint manufacturing process typically involves the following steps:

Selection of raw materials

The first step in the paint manufacturing process is the selection of raw materials. These include pigments, binders, solvents, and additives that will be used to create the desired paint color and properties. The selection of raw materials is crucial to the quality of the final paint product, and manufacturers carefully choose each component to ensure that it meets their specifications.

Mixing and blending

Once the raw materials have been selected, they are carefully mixed and blended in the proper proportions to create the base paint mixture. This is typically done using large industrial mixing equipment, such as blenders or agitators, to ensure thorough and consistent mixing.

Grinding and milling

After the base paint mixture has been created, it must be ground and milled to achieve the desired consistency and smoothness. This is typically done using a mill, which can be either a horizontal or vertical roller mill. The paint is fed into the mill, where it is ground and milled until it reaches the desired consistency.

Quality control and testing

Before the paint is packaged and shipped to customers, it must undergo thorough quality control and testing. This involves evaluating the paint’s physical and chemical properties, such as its color, viscosity, and drying time, to ensure that it meets the manufacturer’s specifications and customer requirements.